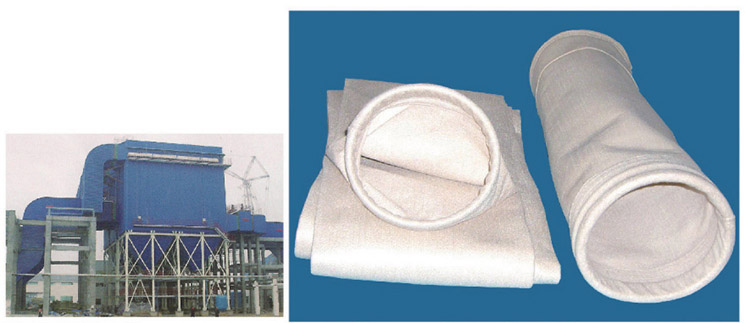

PPS filter bag is the PPS polyphenylene sulfide (PPS) fiber produced in Germany by our company. According to the production process of other high temperature resistant filter felt, the filter bag is produced and processed. It is one of the main varieties of high temperature resistant filter bag. PPS acupuncture filter bag has excellent performance in the following applications.

1. Working temperature: 170°C; short-time working temperature: 232°C; melting point: 285°C; limiting oxygen index: 34~35.

2, oxygen content in 15% or less of the occasion can be applied.

3, the fuel containing sulfur or flue gas containing sulfur oxide, has been proven to be acid and alkali corrosion resistant, chemical resistance is very strong fiber.

4. Wet places in the flue.

5. PPS filter bags have excellent performance records when the gas cloth ratio is as high as 5:1 for on-line ash cleaning and 6:1 for off-line ash cleaning at 190°C~232°CI. It is widely used in power plants.

PPS high temperature resistance, acid-alkali resistance needle filter felt

Material: Polyphenylene sulfide

G /m: 500

Thickness: 2.0

Operating temperature (instant) : 232°C

Working temperature (long-term) : 80 -- 190°C

Fracture strength (meridional) : 1200N/5X20cm

Fracture strength (zonal) : 1400N/5X20cm

Acid resistance: excellent

Alkali resistance: good

Air permeability: 12-16

Post-treatment: Singeing, calendering, heat setting, PTFE impregnation, teflon coating

PPS fibers have complete strength retention and intrinsic chemical resistance, allowing excellent filtration performance in harsh environments and ideal service life. PPS filter felt is an ideal filter material for pulsed ash precipitator, such as filter coal boiler, waste incinerator and fly ash collection treatment of power plant.