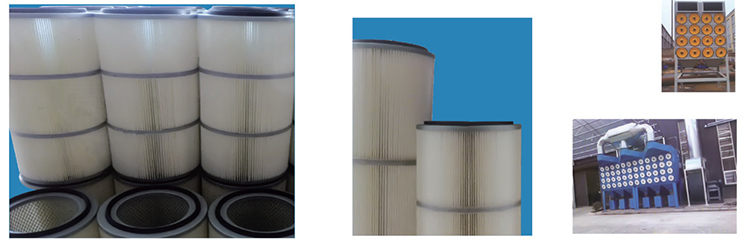

1. Filter materials of the filter cartridge can be domestic or imported polyester long fiber non-woven cloth (can be coated, oil proof, waterproof, static proof, flame retardant treatment), polyester long fiber filter paper, glass fiber filter material, etc.

2. Adopt international advanced automatic discount technology, with even clearance and reasonable folding height.

3. The end covers at both ends of the filter cartridge are stamped with 0.8mm anti-rust steel plates (not easy to deform), and the end cover is bonded to the filter material with special two-component adhesive bonding (ensure that the end cover is tightly connected to the filter material without gaps).

4. The internal and external support and protection skeleton shall be made of diamond shaped mesh with high strength and good anti-corrosion performance of 0.6mm or above. The large support force can prevent the filter cylinder from being blown out, blown out, blown out, absorbed and deflated, and the reinforcement can be treated according to special purposes.

5. The connection between the filter barrel and the slide plate adopts low hardness and high strength foaming sealing rubber ring to ensure no dust leakage. The internal filter material is fixed with glue (or fixed with fastening belt) to ensure that the air volume and filter area of the filter tube are uniform for the back blowing of the electromagnetic pulse valve.

6. Application: surface treatment of shot blasting (spraying), polishing and rust removal, powder spraying coating, metallurgy, cement, tobacco, casting, storage battery, packaging, carbon black, chemical industry, electrostatic industry, welding dust, etc

| 规格 Specification

|

Fi Iter area |

Treated a i r voIume |

Processing air speed |

Initial resistance of fiIter eIement |

|

350X660 |

11.88~12. 1 |

≤720 |

0. 5~1.0 |

≤150pa |

|